Quality circles are small groups of employees that meet regularly to solve problems affecting their work area, and to enhance the quality and productivity of their work.¹ They assemble on a regular basis to identify, analyze and solve work related problems. This method emphasizes continuously improving quality, productivity and employee involvement.

Quality circles typically have a supervisor or elected team leader. As well, a specially trained manager usually helps facilitate the group from the beginning, providing training in problem solving, statistical control, and group processes as well as making sure things in the group run smoothly.² Teams that are assembled may use techniques such as brainstorming, cause and effect and sampling and charting methods to solve various problems related to their work.

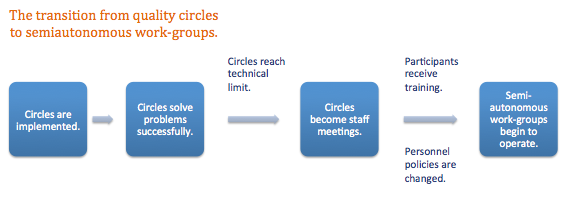

When mature, true quality circles become semiautonomous work-groups, having acquired a history of successful solving problems, technical training, and the confidence of management.

According to Lawler and Mohrman, although American and Japanese quality circle programs are very similar, programs in Japan typically place a greater emphasis on statistical control, employees often meet on their own time, and employee rewards are more often tied to the performance of the organization.²

References:

1. Introduction to Human Resource Management. (2004). Journal of ICFAI. ICMR Publications.

2. Lawler, Edward E., and Susan A Mohrman (1985). Quality circles after the fad. Harvard Business Review. Jan-Feb. 64-71.