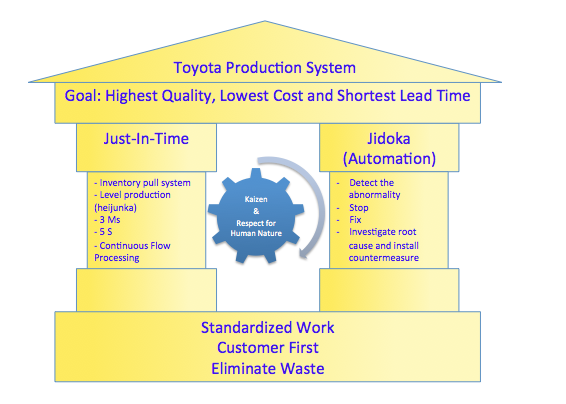

The Toyota Production System (TPS) is a lean manufacturing system that relies on two pillars: autonomation and just-in-time. Autonomation (or jidoka) means separating the work between what workers can do and what machines can do. It also emphasizes that everyone from management to assembly line workers have a responsibility for quality, and that the entire production line should be stopped if a defect is found. Continuous improvement (kaizen) is stressed, where immediate problems are fixed and workers are empowered to evaluate root causes and implement new solutions. This is an employee-driven and teamwork-oriented process.

At the same time, just-in-time inventory management is used. This means that inventory comes based on a pull-system (when parts are needed down the line, it signals to earlier parts of the supply chain that more parts are needed). Even simple signals like an empty spot on the shelf can be used to signal that more inventory should be pulled. Level production is also an important component of just-in-time. Level production means that goods are produced at a constant rate during the production process so that goods further down the production line may be produced at a constant rate as well. Because they don't keep a large amount of inventory on hand, having level production is important to ensure that parts become available when parts are needed. Similarly, quality management is an important component of just-in-time, since there is not a stockpile of inventory to replace defective parts. Autonamation plays an important role in quality management.

Toyota Production System "House"

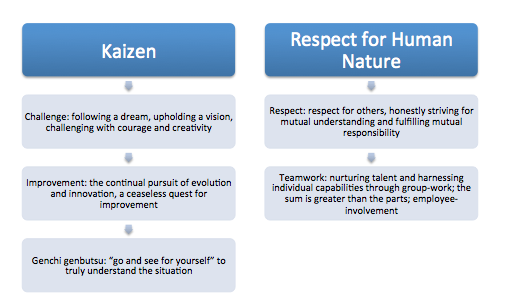

To make the Toyota Production System work, Toyota has embraced a specific set of values that help define the organization's culture. These values were laid out in Toyota Way 2001. There are two pillars to Toyota's value system that help drive the organizational culture at Toyota and ensure the success of TPS. These two pillars are Kaizen (continuous improvement) and respect for human nature.